FAQS

We've put together several frequently asked questions regarding live production for breeders (per hen day) and meat ducks (average performance including mortality and condemnations).

Breeders

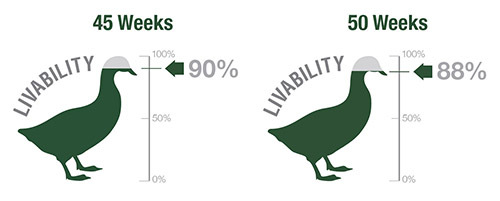

45 week livability is 90%; 50 week livability is 88%

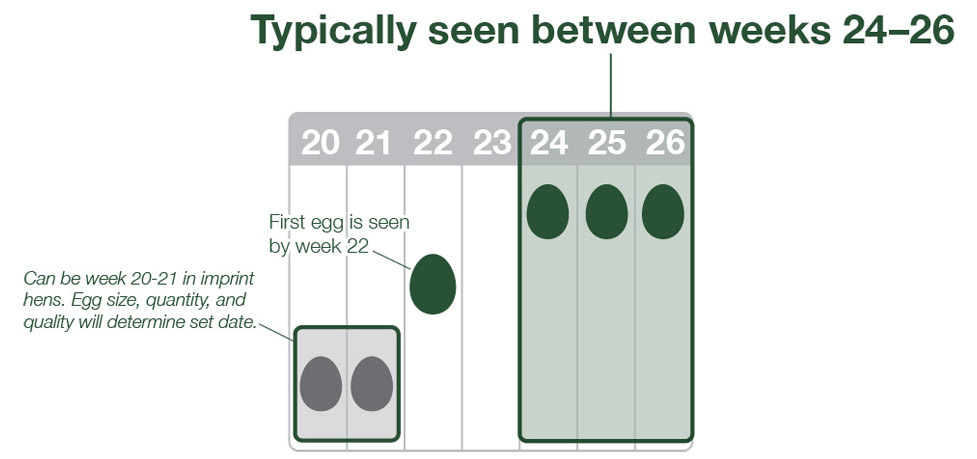

First egg is seen by week 22 and can be week 20-21 in imprint hens. Egg size, quantity and quality will determine set date, typically seen between week 24-26.

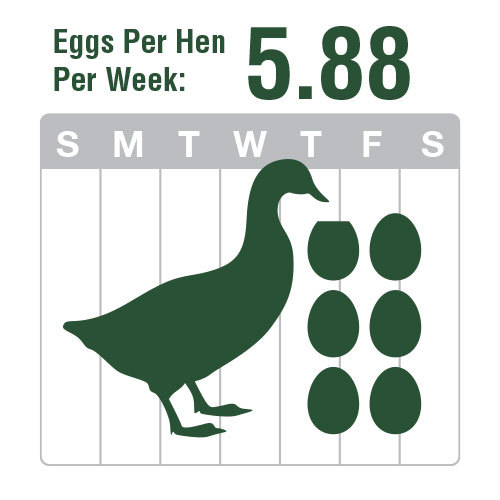

5.88 for 50 weeks of lay

88-90 grams

242 day-olds for 50 weeks of lay

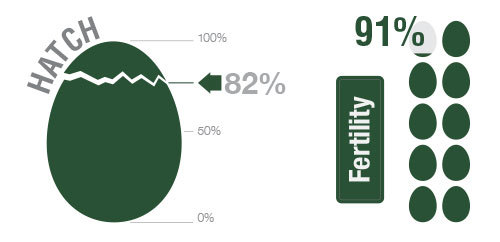

91% Fertility and 82% Hatch for 50 weeks of lay

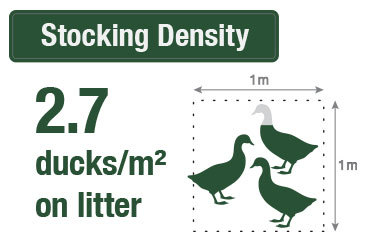

2.7 ducks/m2

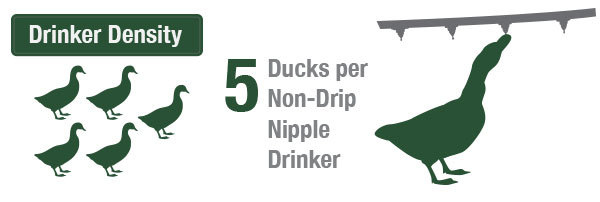

We recommend non-drip nipple drinkers at a density of 5 ducks per nipple.

Meat Ducks

FCR - 1.78; Live Weight - 3.11 kgs; Age to Plant - 35 days

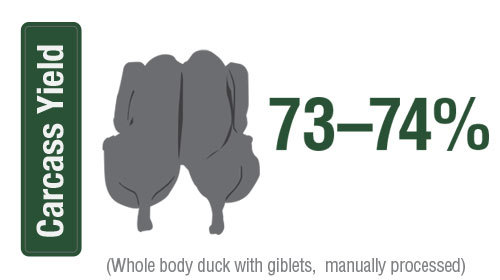

73-74% (whole body duck with giblets, manually processed)

2 Stage, Starter/Finisher

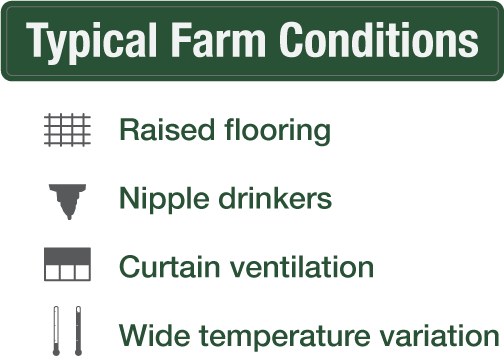

Raised flooring, nipple drinkers, curtain ventilation with wide temperature variation

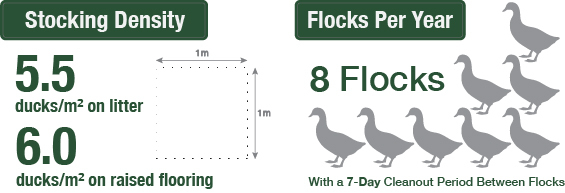

Stocking Density: 5.5 ducks/m2 on litter; 6.0 ducks/m2 on raised flooring

Flocks Per year: 8 flocks with a 7-day clean out period between flocks

- More lean meat yield, less fat and less skeletal waste.

- More sustainable production with less environmental impact per kg of lean meat produced.

- More desirable consumer preference for more edible lean meat and less fat/bone waste.

- This varies by location feed cost, utilities, labor and other factors.

- Higher feed and farm overhead cost production models will see greater advantages.

- Higher value-added processing will see more benefits from greater meat yield.

- More live weight through the farms in less time reduces both overhead and unit cost.

- Higher plant yield reduces finished unit cost down.

- Lower FCR impacts feed cost that drops directly to the bottom line.